PLASTIC FLEXIBLE TUBES

Polyethylene tubes are a versatile, safe, and highly customizable packaging solution widely used in the cosmetic, pharmaceutical, and food industries.

They can be produced in different densities—HDPE, LDPE, and LLDPE, also in combination—and manufactured in sizes ranging from 5 ml to 400 ml with diameters from 19 to 60 mm, offering maximum design flexibility.

Polyethylene ensures excellent chemical resistance and good barrier properties, guaranteeing product protection and functional performance. A full range of aesthetic customization is available through multiple printing technologies: Lithographic printing, Screen printing, Flexographic printing, Hot stamping, Full-wrap or partial labels.

Tubes can also be produced using PCR (post-consumer recycled polyethylene), reducing the use of virgin plastic and supporting more sustainable, circular production models—an increasingly important requirement in the cosmetic industry and among environmentally conscious consumers.

COEX tubes offer a highly advanced packaging solution, featuring a five-layer multilayer structure designed to provide superior protection.

This architecture acts as an effective barrier against oxygen, vapors, solvents, and aromatic components, ensuring optimal preservation of the product's integrity.

They are particularly suitable for high-concentration cosmetic formulations, products with strong fragrances, as well as for pharmaceutical, food, and industrial applications.

Available in diameters ranging from 25 to 60 mm, these tubes can be tailored to meet a wide variety of technical and application requirements.

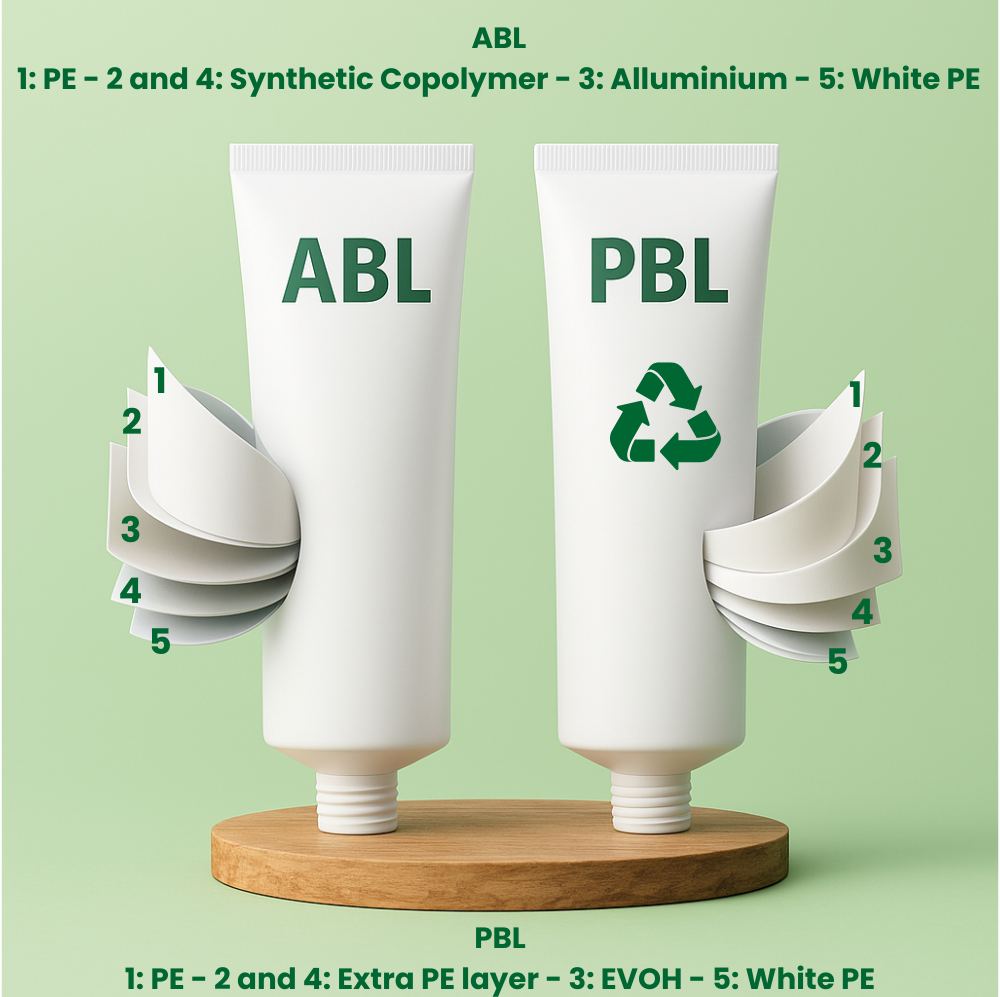

ABL (aluminium barrier laminate) and PBL (plastic barrier laminate) tubes provide a high-performance packaging solution designed to protect even the most sensitive formulations, ensuring effective barrier properties and long shelf life.

They offer extensive customization with up to 9 printing colors and decoration techniques such as flexographic printing, screen printing, hot stamping, and digital printing, delivering a modern, premium appearance.

Available in thicknesses ranging from 275 μm to 400 μm, they allow the selection of the most suitable internal barrier: aluminum for ABL and EVOH for PBL, ensuring optimal performance tailored to the product and the customer's needs.

SPECIAL PLASTIC TUBES